Chunhui Intelligent Control successfully listed on the Shenzhen Stock Exchange on February 10, 2021, stock code: 300943.SZ. Although we have entered the capital market through the listing, we are still a small company, and our three product groups—heating technology, energy control, and automotive electromechanical—are all facing numerous challenges in technological innovation, market expansion, and sustained profitability. The company's board of directors has remained calm and clear-headed, and promptly proposed the “re-entrepreneurship” strategy to proactively face the new challenges of the next decade.

re-entrepreneurshipIt is both a process and a result or goal! As an overall objective, it takes the professional business unit as the basic accounting unit, and through diligent operation and management, aims to achieve three indicators:

First is to becomea leader in the professional market,which means being in a leading position in both technology and market share. In fact, this indicator is the purpose of our long-standing and persistent “big fish in a small pond” strategy;

Secondly, itsprofitabilityshould beleadingin the industry. Having profitability is the natural instinct of a business organization, and the true standard of excellent management is whether you can generate higher profitability than your competitors;

Finally, it must possessunique core competenciesfor sustained growth. In fact, there are quite a few companies with the above two advantages, however, we find that the life cycle of those companies is very short! That is because merely focusing on profitability and industry status is not enough; unless you have unique and inimitable core competencies, only then can you operate the company in a long-term and sustainable manner. The establishment of these three indicators is because we must uphold and adhere to Chunhui Intelligent Control's values: valuable growth and sustainable development!

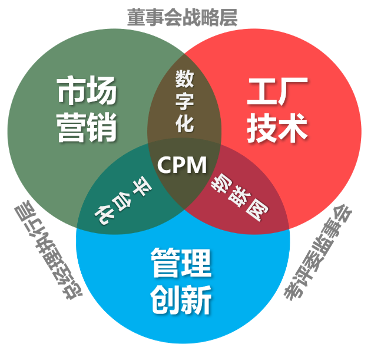

These three goals mean that we must improve our capabilities in people and organization, product services, and growth innovation. The board of directors regards the elite class's tiered talent plan and the implementation of CPM (Chunhui Lean Management Model) as the bridge to a century-old Chunhui. Therefore, how to enable elite class members to use CPM practices, leveraging digitalization, platformization, and IoT technology tools to embed management concepts into factory technology, marketing, and management innovation, has become particularly urgent and important. Thus, “digitalization” is the first stop in the study tour!

What is the essence of an excellent digital factory? How should Chunhui Intelligent Control transform into a digital factory?

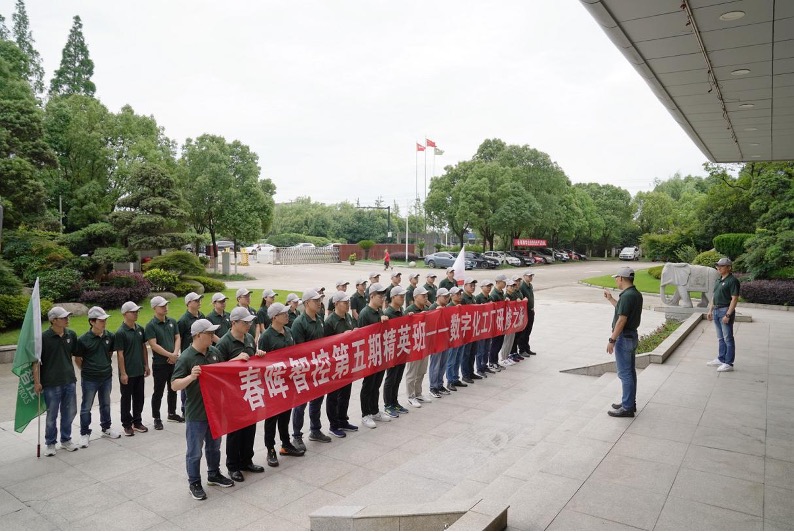

On June 15, all members of Chunhui Intelligent Control's fifth Elite Class, led by Chairman Mr. Yang Guangyu, embarked on a three-day study tour with the above questions, to explore the essence of an outstanding digital factory.

Before departure, the chairman required the students to: uphold 100% strong will, 100% scientific methods, and 100% strict execution, and to approach the digital factory transformation with a learning mindset.

Society is currently in a period of rapid development of the information age and the intelligent age, making digitalization imperative for enterprises. To cultivate digital factory talents, the digital study tour of the fifth Elite Class is Chunhui Intelligent Control's journey of seeking innovation, truth, and survival.

The students visited the final assembly workshop of SAIC Volkswagen's third plant, learned about the German lean model of the Volkswagen factory, and gained insights into various approaches to lean improvement worldwide, broadening their horizons and gaining a new understanding of lean improvement.

Chunhui Intelligent Control will also start from these aspects, drawing on the strengths of others to make up for its own shortcomings. Compared with the existing CPM (Chunhui Lean Production Management System), Chunhui Intelligent Control still has a long way to go. If Toyota and Volkswagen are soaring eagles on the road of lean improvement, then Chunhui Intelligent Control is still a fledgling bird spreading its wings. As long as it persists on the CPM path, one day it will also gallop under the sky of lean improvement.

On the second day, the students visited AUO's digital factory in Suzhou Industrial Park, listened to the introduction of AUO's digital transformation journey, and learned about the value of digital transformation in manufacturing enterprises. The application of digital technology has promoted innovation in production efficiency, management efficiency, and organizational efficiency, thus achieving lean factory operations and providing more and better solutions for lean production concepts.

During the afternoon visit to Honeywell, students experienced the operation of the production line on site, learning how to empower the production line through lean tools and how to consolidate results through culture to achieve disciplined organizational behavior.

The students visited NIO's “Future” factory in Hefei. Innovation is the driving force of our society's development. The older generation of automotive professionals might not have imagined that today's new energy vehicle manufacturing centers have achieved over 90% automation. The factory adopts highly mechanized automated production, with almost no manual intervention throughout the process, making it a standard modern, automated, and integrated high-tech factory. The students witnessed the crystallization of modern technology, showcasing the direction of future digital factories through efficient automated assembly lines. Chunhui Intelligent Control should also move in this direction, as integrated and automated production methods can effectively reduce costs, lower error rates, and improve product quality, gradually transforming “Made in China” into "Intelligent Manufacturing in China."

Only by running tirelessly can we see the direction of the future. As an example, the NIO factory showed the trainees what the “future” looks like. After the visit, the trainees were deeply inspired and came up with many different ideas. Through their enthusiastic discussions, each person also has their own “future” factory in mind. We believe that after the study tour, they will put their ideas into action, and through their own innovation and practice, create a new “future” for Chunhui Smart Control!

Grasping the pulse of the times, the journey of seeking innovation, truth, and survival in digital training will lay a solid foundation for a century-old Chunhui!

At the same time, we look forward to the elite class embarking on a new study tour themed on “platformization” and the “Internet of Things,” striving tirelessly to achieve the goal of “re-entrepreneurship”!

“Chunhui Elites, Victory in the Future!”