To all employees of Chunhui Intelligent Control:

Dear colleagues, hello everyone!

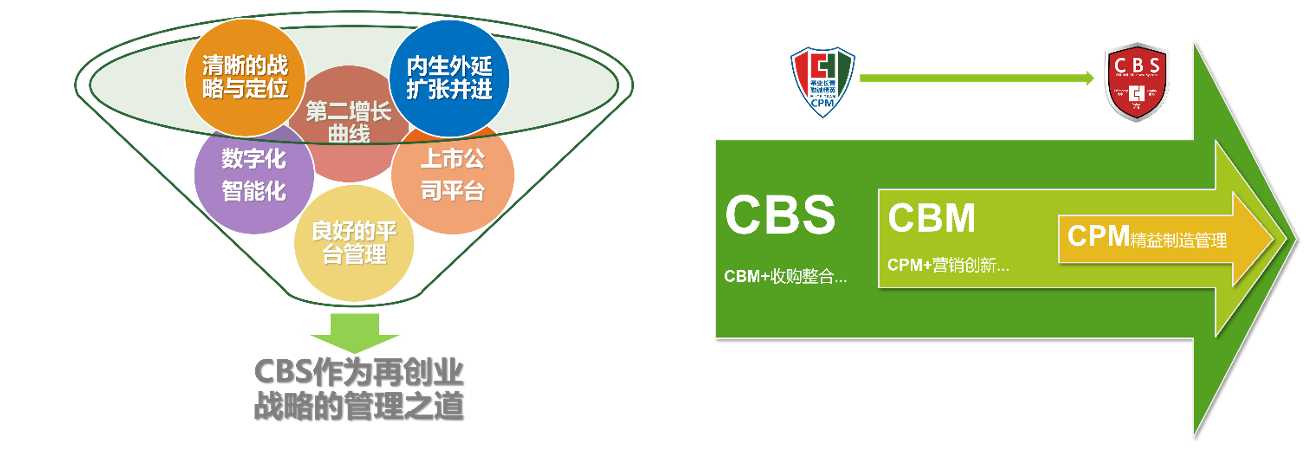

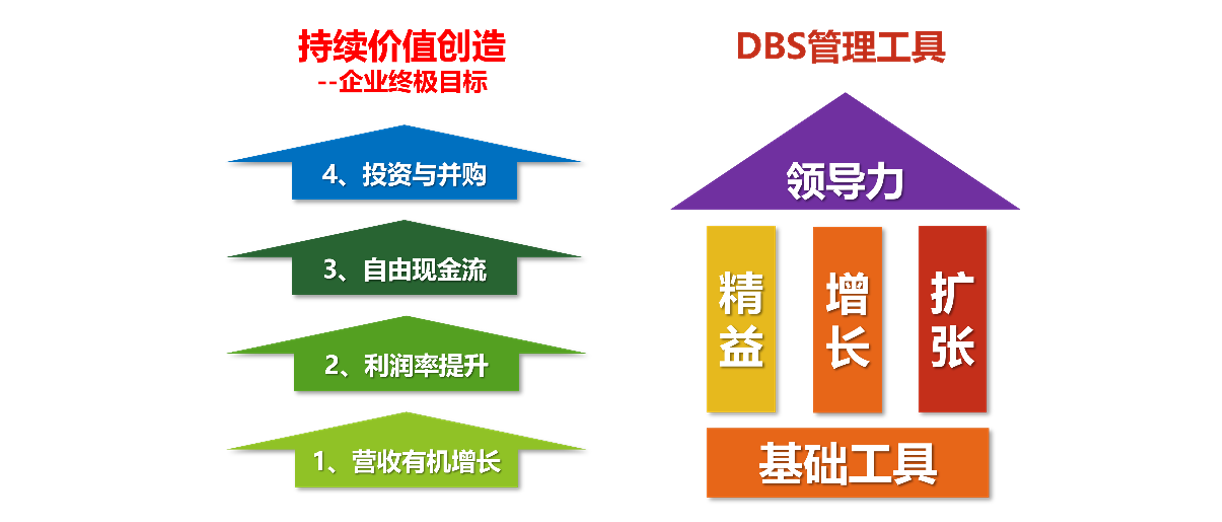

Today, on behalf of the Board of Directors, I announce that we will designate the 2025-2030 period as the re-entrepreneurship phase of Chunhui Intelligent Control, and the company will fully introduce and learn from DanaherDBSfor improvement,CBSmanagement model, and establish according to the current situation and industry backgroundthe second growth curve, endogenous and external expansion in parallel, digitalization, intelligence, and internationalization...and other strategic plans. Chunhui Intelligent Control will officially upgrade and transform fromlean manufacturing-orientedCPM to a comprehensive, holistic, and systematic CBS management approach.!

Ourre-entrepreneurshipgoal is: to let everyone forget past successes, while reviewing and summarizing lessons learned, withopenness, perseverance, and progressSpirit, once again establishing outstanding and challenging goals, joining hands to create a better future together—Centennial Chunhui!

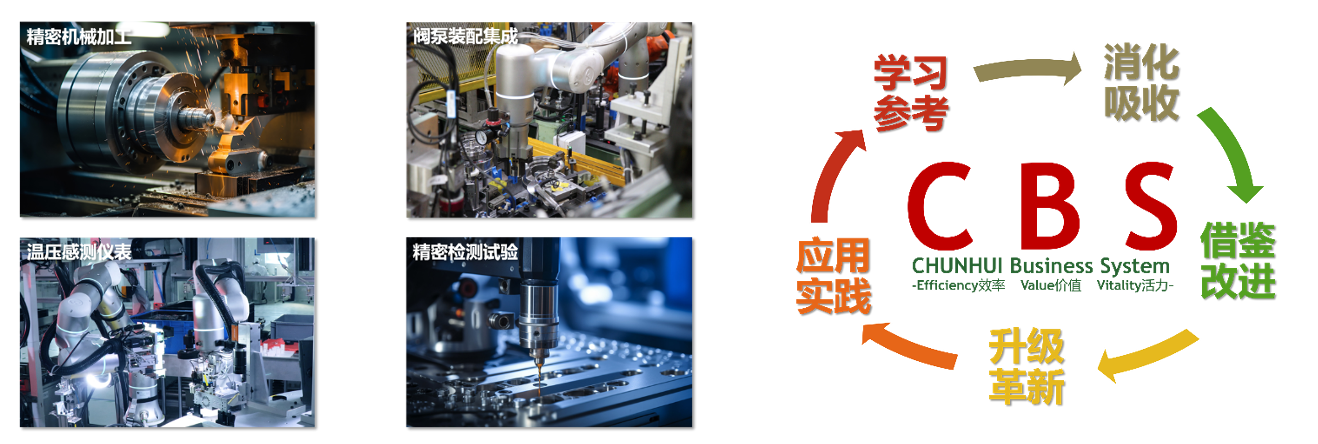

Therefore, in comprehensive implementationCBSBeforehand, we must clearly understand and recognize, under the current Chunhui Intelligent Control resources and capabilities, what is most suitable to do or which industries without advantages should be abandoned. The board has decided that in the re-entrepreneurship phase of 2025-2030, we will use the digital foundation and dual-carbon background goals as“Smart City& Green Energy”as the direction for industrial strategic development, choosing to focus on:Precision machinery, control valves& pumps, temperature and pressure sensing instruments & actuators, intelligent control systems & software…Operating in the vertical specialized niche markets where we are most skilled and resource allocation is most efficient as the company's business strategy, through efficient and innovative management, aiming to make each business becomethe largest and fastest-responding fish in its niche pond, as the execution path and business model for Chunhui Intelligent Control's medium and long-term strategy!

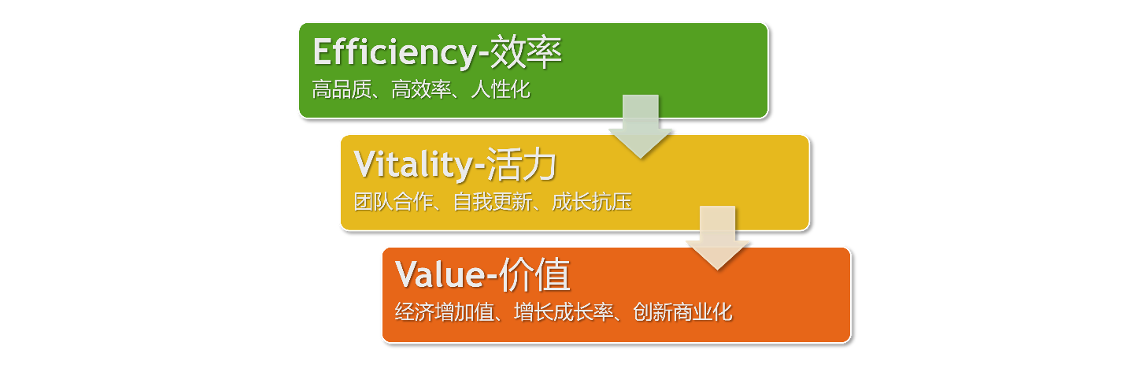

CBS(CHUNHUI Business System) is the lean manufacturing-based practice initiated by Chunhui Intelligent Control in 2012CPM (CHUNHUI Production Management) On this foundation, after successfully being listed on the Shenzhen Stock Exchange in 2021, as part of the 2030 re-entrepreneurship strategy to achieveEfficiency, vitality, valueExecution management model for the three-element objectives.

CBSOn one hand, execution will continue to focus on lean manufacturingCPMupgrading and improving on this foundation; on the other hand,DBSlearning and drawing on innovation and reconstruction, centering on the three core elements of efficiency, value, and vitality to achieve the ongoing management goals of endogenous business growth, extensive system development, and acquisition-driven integrated expansion advancing in parallel.

The re-entrepreneurship strategy will concentrate resources at headquarters, BU, vertical business units, and across various business horizontals for efficient, valuable, and dynamic management, expanding new channels, new products, and new markets. Focusing on the smart city & green energy industries, we strive for the “big fish in a small pond” strategy, aiming for leadership in multiple specialized niche markets.CBSWe will strive to achieve our goals and make them the gene of a century-old Chunhui through the execution path of

the re-entrepreneurship strategy!CBSBefore executingDBSI believe it is necessary to have a simple understanding of the

DBSmanagement model! (Danaher Business System) is a world-renowned lean management system created and successfully practiced by Danaher Corporation. It is not only Danaher’s core competency and the cornerstone of its sustained success, but also regarded as one of the global benchmarks for lean management.

DBSUnderlying business operating system principles:

DBSThe core logic and objectives of

- can be summarized as follows:Customer-centric: The ultimate goal of all improvements is to better meet customer needs and create customer value. The voice of the customer (VOC) and market demand are the fundamental drivers of all DBS activities. Process improvement, quality enhancement, and cost reduction must ultimately aim to improve customer satisfaction and market competitiveness.

- Eliminate waste(Muda): Drawing on the essence of the Toyota Production System, it considers all activities that do not directly create value for customers as waste (such as waiting, overproduction, transportation, defects, over-processing, inventory, unnecessary movements). Through systematic tools and methods (such as value stream mapping, 5S, standardized work, single-piece flow, pull system, quick changeover, mistake-proofing), continuously identify and eliminate waste at every stage of the process.

- Continuous improvement(Kaizen): Treats improvement as a daily habit and culture, not a one-time project. Encourages all employees, from frontline operators to senior managers, to actively participate in discovering problems, analyzing root causes, and implementing solutions.PDCACycle-driven, strictly follows the Plan-Do-Check-Act cycle to ensure improvement measures are effective and standardized.

4. Fact- and data-based decision making: Emphasizes speaking with data and facts, avoiding subjective assumptions. Uses various tools (such as statistical process control, root cause analysis) to collect and analyze data, accurately pinpointing the root cause of problems. Establishes key performance indicators to measure process performance and improvement effectiveness, ensuring the improvement direction is correct.

5. Respect and empower employees: Firmly believes that those who best understand process problems and improvement opportunities are the employees directly involved in the work.DBSAims to create a safe environment that encourages employees to raise issues and improvement suggestions. Provides employees withDBStraining in tools and methods, empowering them with the authority and ability to identify, analyze, and solve problems.

6. Standardization and flexibility: Establishes best practices, forms standardized work from proven effective methods to ensure stability of quality and efficiency, and provides a benchmark for continuous improvement.

DBSThe core objectives to be achieved

1. Operational Excellence: Achieve world-class operational performance by eliminating waste, optimizing processes, and improving quality and efficiency. This is reflected in shorter delivery cycles, lower costs, higher quality (lower defect rates), higher production efficiency, better inventory turnover, and a safer working environment.

2. Continuous Growth and Profitability Improvement: The efficiency improvements, cost savings, and quality enhancements brought by operational excellence directly translate into higher gross margins, profit margins, and cash flow. Higher efficiency and quality enable the company to offer more competitive prices and better products/services, thereby winning market share and supporting business growth. Therefore,DBSis the key driving force for Danaher to achieve outstanding financial performance.

3. Building a Culture of Continuous Improvement: Internalize “continuous improvement” into the organization's DNA and into every employee's mindset and behavioral habits. The goal is to create a self-driven organization that continuously learns and proactively seeks progress. This culture itself becomes a sustainable competitive advantage that is difficult for competitors to imitate.

4. Talent Development and Employee Engagement Enhancement: Through participation in improvement activities, receiving training, and being empowered to solve problems, employees' skills are enhanced and they gain a sense of achievement. When employees see their suggestions valued and implemented, and see the work environment continuously improving, their job satisfaction and engagement increase significantly. Employees become the main drivers of improvement rather than passive recipients.

5. Supporting M&A Integration and Value Creation:DBSis the key to the success of Danaher’s “acquisition-integration-improvement” business model. After acquiring a new company, quickly introduceDBS, identify improvement opportunities, rapidly enhance the operational performance and profitability of the acquired company, and unlock synergy value.DBSprovides a strong integration framework and value creation engine.

DBSStarting from customer value, through full employee participation, using lean tools and methods, based on facts and data, continuously identifying and eliminating waste, pursuing operational excellence, and ultimately achieving sustainable business growth, profitability improvement, and competitive advantage. Its ultimate goal is to build an organization with a strong continuous improvement gene, highly engaged employees, and the ability to continuously self-renew and create outstanding value.

DBSThe success of lies in the fact that it is not just a set of tools, but a deeply ingrained management philosophy, mindset, and company culture. Danaher, throughDBSAchieved decades of sustained growth and outstanding shareholder returns, proving the strong vitality of this system.DBSIts successful implementation is by no means accidental; it relies on a set of structured best practice paths and methods that have been validated over decades, with a core focus on systematization, cultural integration, and continuous iteration. Its ongoing power to create greatness comes from proactive benchmarking, clear strategy, and adherence to common sense.

In view of this, Chunhui Smart ControlDBSdraws on and learns fromCBSWhether implementation can succeed will depend on the following key elements:

I.Top-level commitment and full participation are prerequisites: Without heartfelt, sustained, and visible commitment from top management and participation from all employees,CBSfailure is inevitable.

II.Cultural transformation is the core: Shifting from “command and control” to “empowerment and improvement,” from “fear of mistakes” to “embracing problems.”

III.Patience and perseverance:CBSIt is a marathon, not a sprint. It takes years or even decades of continuous investment to see deep-rooted culture and significant returns. Danaher DBS itself has also undergone decades of evolution.

IV.Tailored Teaching According to Aptitude: Although DBS has a universal framework and tools, implementation must be adjusted, improved, and innovated based on our own industry, competitive position, industry cycle, scale, and cultural characteristics.

V.Focus on Customer Value: Improvement activities must ultimately aim to enhance customer satisfaction and market competitiveness.

VI.Results-Oriented: Continuously track financial and operational performance indicators (such as cash flow, gross margin, inventory turnover, quality cost, delivery cycle) to demonstrateCBSthe value brought.

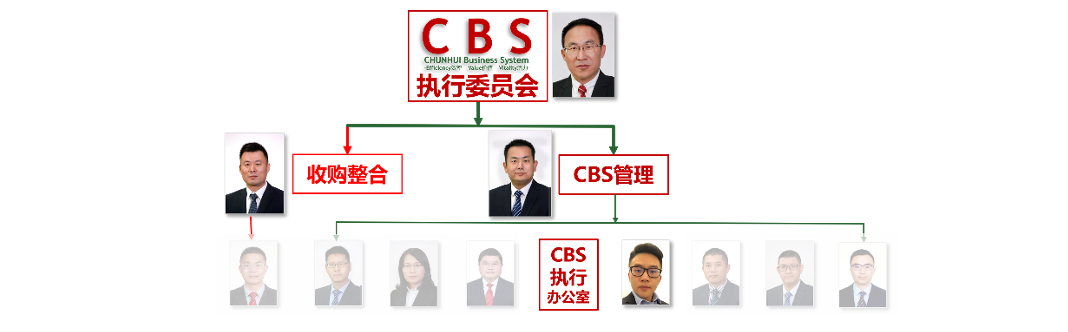

Dear colleagues,CBSThe best practice path is essentially a systematic project driven by top management, evolving from pilot to full-scale, from tool application to cultural integration, and continuous iteration. Therefore, the board will establish anCBSExecutive Committee, and I will serve as theCBSExecutive Committee Director, toDBSlearn, digest, absorb, benchmark, apply, and deeply practice according to the six elements!

I solemnly request that the company's middle and senior management face up to this.CBSWe must unswervingly implement, ensure the active participation of all employees, and persist in the long term.Never look for excuses, never lower standards, never give up easily.!

Thank you all!

Zhejiang Chunhui Intelligent Control Co., Ltd.

Chairman Yang Guangyu

July 28, 2025